Design Optimization of Brake Disc

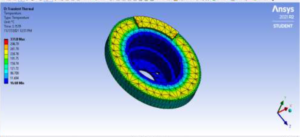

Objective: Optimize the geometry of a brake disc to decrease its total volume, minimize the max stress and temperature.

Action: Performed static, thermal and modal analysis to reduce max. stress and mitigate resonance. Optimized the design by using MOGA algorithm in Ansys.

Results: Reduced max. stress by 8%. Reduced the total volume by 10%

Design and Fabrication of bio-inspired salamander robot

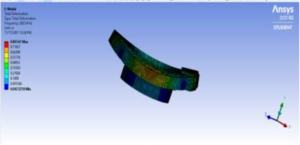

Objective: To fabricate a light-weight, low-cost robot using lamination techniques so that it is able to traverse granular media.

Action: Modeled the 3 segment body of a salamander in SolidWorks, used computational tools in Python to model the system kinematics and performed experiments for system characterization.

Results: Successfully fabricated the robot to traverse granular media.

Design and Fabrication of braiding machine

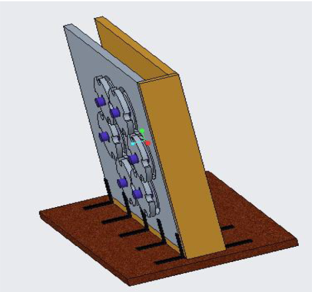

Objective: Design and fabricate a braiding machine for overbraiding a pressure vessel.

Action: Designed the machine in Creo considering different parameters like rotational speed, gear radius and its effect on the braid angle. Applied DFx principles to manufacture different machine components.

Results: Fabricated the braiding machine to overbraid a pressure vessel of size10mm.

Comparative analysis of bonnet made out of different materials for pedestrian safety

Objective: Determine best performing material among CFRP, FFRP (Flax-Fibre), GFRP to be used for automobile bonnets.

Action: Developed an FEA model, adhering to Euro-NCAP regulations; Used appropriate meshing strategies to reduce computational time by 20%.

Results: Found Flax composite to be the best performing material among CFRP, FFRP and GFRP; though not enough to replace Steel or Aluminium composites