Intel

Graduate Technical Intern

July ’22 – April ’23

I interned with the STTD Tooling Team at Intel Chandler, which is responsible for the back-end testing of chips in the HVM environment.

My daily responsibilities included:

- Support Lab Qual (Validation and Verification) process of Intel’s next-gen interconnects.

- Perform statistical analysis to determine whether the tooling meets reliability criteria.

- Communicated with suppliers to understand failure Root-Cause and address issues with collaterals.

- Led pathfinding projects to enable new test technologies.

Key learnings:

- Learnt to use a variety of lab equipment including

- MPT Cyclers

- Keyence VHX-5000 series optical microscope – for visual inspection and Failure Analysis.

- Nikon VMR-6555 – for automatic dimensional data collection.

- Instron 6800 – automatic Force-Displacement data collection.

- Statistical analysis using variability charts, box plots, bubble plots in JMP.

- Identify key process and noise parameters through DOE’s

- Model Based Problem Solving (MBPS) techniques.

PARA Lab, ASU

Research Aide

Aug ’21 – Jun ’22

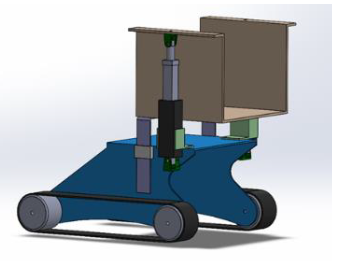

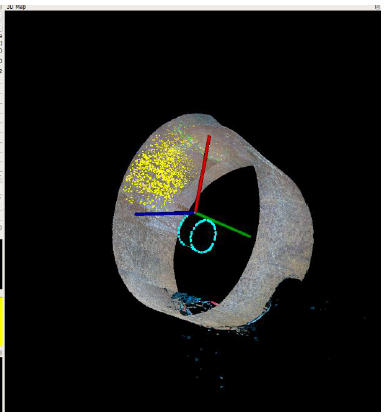

Problem Statement: Develop a novel In-line inspection (ILI) robot which can travel inside gas pipelines for preventive maintenance, as a part of a US-DOT project.

Contributions:

- Improved the robot functionality by integrating a height-adjustment mechanism to the existing platform.

- Enabled 3D reconstruction of the pipe surface through a Simultaneous Mapping and Localization (SLAM) algorithm.

- Recieved MORE scholarship of $1500 and funding for hardware and supplies required to complete the project.

Possibillion Technologies

Mechanical Design Intern

Jan’ 21 – April’ 21

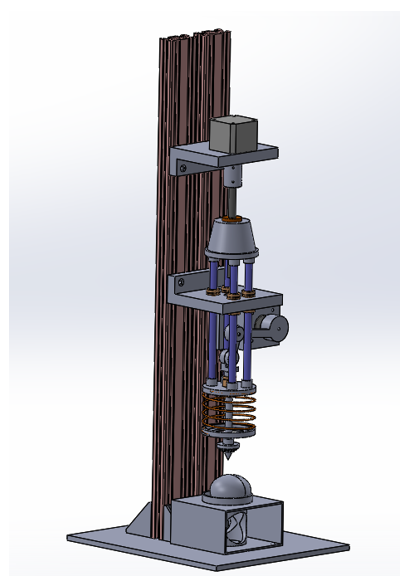

- Managed products for a vending machine through proof-of concept, testing, debugging and production stages.

- Prepared numerous design configurations in SolidWorks; worked in conjunction with embedded developer team to come up with the best possible design.

- Implemented integration of holding and punching mechanism, thereby decreasing serving time by 25%. Use continuous improvement strategies to improve part obsolescence by 30%

Central Leather Research Institute

Research and Development Intern

- Managed products for a vending machine through proof-of concept, testing, debugging and production stages.

- Prepared almost 50 tensile specimens of different materials which differed in critical parameters like orientation angle, infill percentage and pattern characteristics using CubePro Duo printer.

- Performed mechanical characterization, fracture study of the 3D printed specimen using CubePro Duo Printer.

- Suggested best 3-D printer setup resulting in 25% savings in material cost and 15% savings in printing time